Foam board, a lightweight and versatile material, has emerged as a popular choice in various industries, from construction to packaging and art. Its unique properties and adaptability make it a valuable asset, offering numerous advantages over traditional materials.

This comprehensive guide delves into the composition, applications, design, fabrication, finishing, and sustainability of foam board, providing valuable insights into its multifaceted nature.

Foam Board Properties and Composition

Foam board is a lightweight, rigid material commonly used in various applications, including construction, signage, and art projects. It consists of a foam core sandwiched between two layers of paper or plastic.

The foam core is typically made of polystyrene, polyurethane, or polyethylene. Polystyrene foam boards are the most common type and are known for their low cost and lightweight. Polyurethane foam boards are more durable and offer better insulation properties. Polyethylene foam boards are waterproof and resistant to chemicals.

Types of Foam Boards

- Polystyrene Foam Board:Lightweight, low cost, and widely used in construction and signage.

- Polyurethane Foam Board:Durable, provides insulation, and is suitable for outdoor applications.

- Polyethylene Foam Board:Waterproof, chemical-resistant, and ideal for marine and laboratory settings.

Advantages of Foam Board

- Lightweight and easy to handle.

- Rigid and durable.

- Versatile and can be cut, shaped, and painted.

- Cost-effective.

Disadvantages of Foam Board

- Not fire-resistant.

- Can be susceptible to moisture damage.

- Not suitable for structural applications.

Foam Board Applications

Foam board finds applications in various industries due to its unique properties, including rigidity, lightweight, and affordability. It serves diverse purposes in construction, packaging, art, and beyond.

Construction

In construction, foam board is widely used as an insulation material for walls, roofs, and floors. Its insulating properties help regulate temperature, reducing energy consumption and improving overall comfort. It is also employed as a backing material for drywall and as a base for countertops and cabinetry.

Foam board’s lightweight nature makes it easy to handle and install, saving time and effort.

Packaging

Foam board’s protective qualities make it ideal for packaging fragile items. It provides cushioning and shock absorption, ensuring the contents remain intact during transportation. Its lightweight design also helps reduce shipping costs. Foam board is commonly used for packaging electronics, artwork, and delicate machinery.

Art

Foam board serves as a versatile medium for artistic creations. Its smooth surface provides a suitable base for painting, drawing, and photography. Artists also use foam board for model making, sculpture, and architectural prototyping. Its rigidity allows for precise cutting and shaping, making it suitable for creating intricate designs.

Innovative Applications

Beyond traditional uses, foam board has found innovative applications in various fields. For instance, it is used as a temporary flooring material for events and exhibitions, providing a durable and easily removable surface. Foam board is also employed in medical settings as a lightweight and sterile support for medical imaging procedures.

Its versatility continues to inspire creative and practical uses across industries.

Foam Board Design and Fabrication

Foam board design and fabrication involve various techniques to create custom structures and objects from foam board. These techniques encompass cutting, shaping, and assembling the foam board using adhesives, fasteners, and other materials.

Cutting and Shaping

Cutting foam board requires sharp tools like utility knives or saws. Scoring the foam board along the desired cut line helps guide the blade and ensures a clean cut. Shaping foam board can be done using sanders, grinders, or CNC routers.

These tools allow for precise shaping and contouring of the foam board.

Adhesives and Fasteners

Adhesives, such as spray adhesives or contact cement, are commonly used to bond foam board pieces together. Fasteners, like screws, nails, or rivets, provide additional strength and stability to the structure. The choice of adhesive or fastener depends on the desired strength, durability, and intended use of the foam board structure.

Assembly

Foam board assembly involves joining the cut and shaped pieces together using the chosen adhesives or fasteners. Proper alignment and secure connections are crucial to ensure the stability and functionality of the foam board structure.

Foam Board Finishing and Decoration

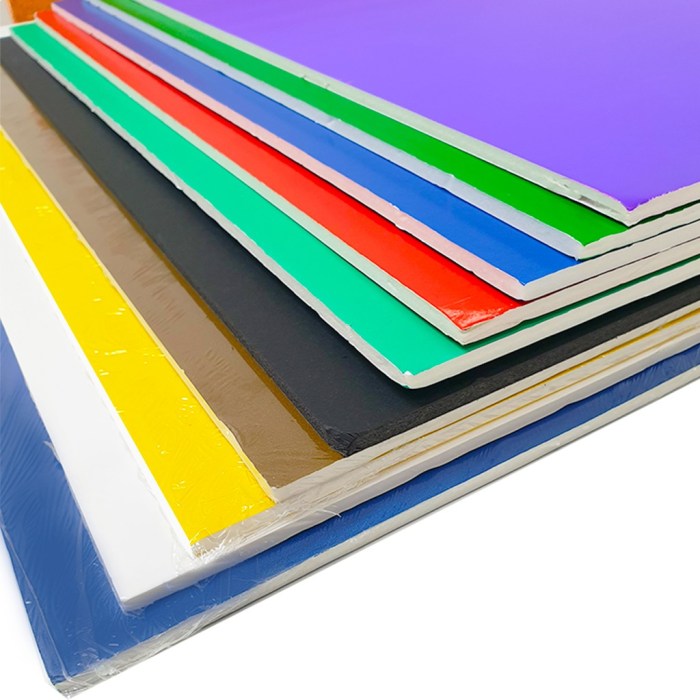

Foam board offers versatility in finishing and decoration, allowing for customization and aesthetic enhancement. This section explores various techniques used to enhance the surface appearance and functionality of foam board.

Painting

Painting is a common method for adding color and patterns to foam board. Water-based acrylic paints or latex paints are typically used due to their ease of application and adhesion to foam surfaces. Use light, even strokes and multiple thin coats to avoid warping or damage to the board.

Lamination

Lamination involves adhering a thin layer of material, such as vinyl, paper, or fabric, to the foam board surface. This provides a durable and protective finish that enhances aesthetics, resists moisture, and prevents scratches. Laminated foam boards are suitable for signage, displays, and other applications requiring durability.

Other Finishes

Other finishing techniques include applying spray paint, faux finishes, or decorative tapes. Spray paint allows for quick and even coverage, while faux finishes can create textures and patterns that mimic natural materials like wood or marble. Decorative tapes add a touch of color and pattern, making them suitable for temporary or decorative applications.

Creating Textures and Patterns

Textures and patterns can be created on foam board using various techniques. Sanding or scraping the surface creates a rough or distressed texture. Using stencils or carving tools allows for precise patterns and designs. Additionally, heat embossing or thermoforming can create raised or indented designs, adding depth and dimension to the foam board surface.

Foam Board Sustainability and Disposal

Understanding the environmental implications of foam board production and disposal is crucial for responsible usage. This section explores the environmental impact, recycling options, and strategies to reduce the environmental footprint of foam board.

Environmental Impact

Foam board production involves the use of fossil fuels and the release of greenhouse gases. Disposal of foam board in landfills can contribute to waste accumulation and potential leaching of harmful chemicals into the environment.

Recycling and Waste Management

Recycling foam board is challenging due to its composition and contamination. However, some specialized recycling programs exist. In the absence of recycling options, proper disposal in designated waste facilities is essential to minimize environmental impact.

Indulge in a night of blissful slumber with a ripple mattress , its unique wave-like design cradling your body for optimal comfort. For a bold and futuristic fashion statement, slip into a pair of yeezy foam runners , their innovative design and vibrant colorways turning heads wherever you go.

Reducing Environmental Footprint

To reduce the environmental impact of foam board usage, consider the following strategies:

- Choose foam board made from recycled materials.

- Use foam board only when necessary and explore alternative materials with lower environmental impact.

- Properly dispose of foam board to avoid contamination and waste accumulation.

Last Point

Foam board’s versatility and adaptability make it an indispensable material for a wide range of projects. Its lightweight, durability, and ease of fabrication offer numerous advantages, making it a preferred choice for various applications. As the demand for sustainable solutions grows, foam board’s environmental impact and disposal options become increasingly important considerations.

By understanding the properties, applications, and fabrication techniques of foam board, individuals can harness its full potential and create innovative and functional projects.

Commonly Asked Questions: Foam Board

What are the different types of foam boards?

Foam boards come in various types, including polystyrene, polyurethane, and polyvinyl chloride (PVC). Each type offers unique characteristics, such as density, rigidity, and fire resistance.

How do I cut foam board?

Foam board can be cut using a sharp utility knife, a hot wire cutter, or a saw. The choice of cutting tool depends on the thickness and density of the foam board.

Can foam board be painted?

Yes, foam board can be painted using latex or acrylic paints. However, it is important to prime the surface before painting to ensure proper adhesion.